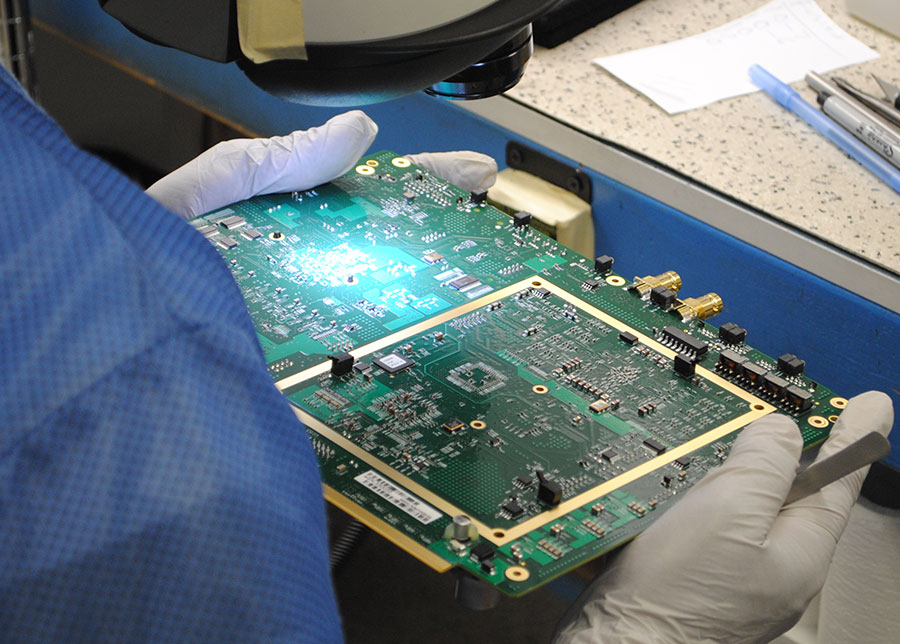

A Recognized Leader In Contract Manufacturing

In support of the DOD as a member of the DIB (Defense Industrial Base) and a manufacturer of Medical Devices, Astronic is classified as an essential business and remains at 100% capacity while implementing and upholding COVID-19 Industrial Guidance for manufacturing, published by the California Department of Public Health, as well as guidelines provided by the CDC. details here

We’ve Been In The Electronics Industry Since 1985

What We Do Best

Industrial Controls

Like Military products, many industrial controls are mission critical and require a high degree of reliability. Up front HALT explorations provide crucial design feedback to help create the optimal product design, and HASS techniques provide verification of the improved design elements.

Commercial Products

Our Commercial Customers benefit from the same documentation and traceability, in addition to process enhancements developed for our DOD and Industrial Controls Customers. Astronic always maintains surplus manufacturing, in order to respond quickly as delivery requirements change for those Customers with higher volume demands.